Apr 13 2020

A new sulfide-based superionic conductor has been successfully developed by Dr Hyoungchul Kim’s research group from the Center for Energy Materials Research at the Korea Institute of Science and Technology (KIST, Acting President Yoon, Seok-jin).

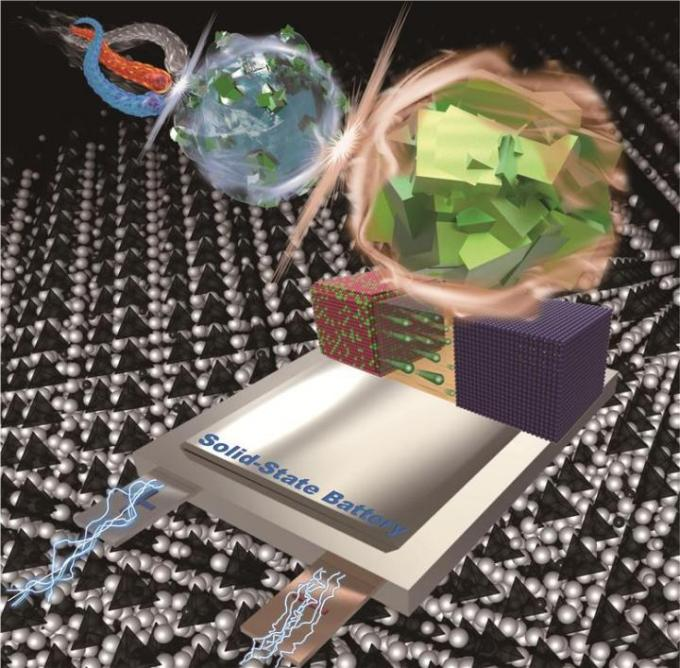

Image Credit: Korea Institute of Science and Technology (KIST)

Image Credit: Korea Institute of Science and Technology (KIST)

This innovative conductor can be utilized in all-solid-state batteries as a high-performance solid electrolyte.

A superionic conductor is a type of material that has high ion transport characteristics similar to 10 to 100 mS/cm of ion conductivity at room temperature. Recently, these materials have been attracting significant attention since they are utilized as electrolytes in numerous electrochemical devices, like sensors, fuel cells, and batteries.

This latest material provides 10.2 mS/cm lithium-ion (Li-ion) conductivity at room temperature and is similar to that of the liquid electrolytes employed in standard Li-ion batteries.

A novel synthesis method has also been reported by the scientists. This technology can cut down the processing time of present-day synthesis technologies by over one-third, and is expected to considerably speed up the large-scale production of superionic solid electrolyte materials and thus support the commercialization of all-solid-state batteries.

The Li-ion batteries, which are presently based on liquid electrolytes, are predominantly used in energy storage devices and electric vehicles. But lately, issues relating to battery safety have been raised a number of times and, therefore, various concerns have been raised regarding the present-day batteries that utilize flammable liquid electrolytes.

To overcome these safety concerns, the all-solid-state battery technology, where all battery components are substituted with solid materials, has recently gained a significant level of attention.

But a solid electrolyte is different from a liquid electrolyte where Li-ions can move freely. It has a low Li-ion conductivity of just 1/10 to 1/100 when compared to that of a liquid electrolyte, because the movement of Li-ions is limited inside a rigid solid lattice. This represents one of the most significant and tricky challenges in the creation of all-solid-state batteries, and its economic and technical value is also believed to be great.

At KIST, Dr Kim’s research group used a sulfide-based crystalline structure, known as argyrodite, to develop a solid electrolyte that has superionic conductivity. Argyrodite is a crystal structure that was found in the mineral of Ag8GeS6 and was discovered by Clemens Winkler in 1886. Of late, intense studies have been performed to substitute the cation sites with alkali metals, like Li, and using them on electrochemical devices.

In the meantime, this crystal structure garnered high prospects for utilization because of its structural stability and high concentration of Li-ions; however, the Li-ion conductivity of this crystal structure continued to be less than 4 mS/cm, because of the structural distinctiveness of Li-ions confined in the octahedral cage within the argyrodite crystal.

The researchers have now created a new Li-ion pathway that crosses the octahedral cage in the argyrodite crystal by applying a method to selectively replace a halogen element—chlorine—at certain atomic positions.

Developed by the KIST research team, the latest solid electrolyte material has a Li-ion conductivity of about 10.2 mS/cm, which corresponds to that of a traditional liquid electrolyte at room temperature, and continues to maintain electrochemical stability under different battery operating conditions.

Reported by KIST researchers, the latest synthesis method has also garnered more attention since the mass productivity of the superionic solid electrolyte materials can now be bigger.

While the traditional solid-state reaction process needs several days of processing time, this research suggested a simple synthesis approach that integrates an infrared rapid heat treatment technology and the nanocrystalline nucleation process to bring down the processing time to less than 10 hours.

Solid-state reaction process is a dry-based material process where one or more solid reaction products are produced with the diffusion of elementary particles. This process usually needs high-temperature heat treatment to promote reactions at a suitable rate.

In the field of all-solid-state battery technology, foreign researchers including Japan are leading the research. In this study, there is great significance in developing a high-performance solid electrolyte material with excellent mass productivity."

Dr Hyoungchul Kim, Center for Energy Materials Research, Korea Institute of Science and Technology

Dr Kim continued, “Synthesis of superionic sulfide materials through rapid process is very likely to be commercialized, and can be widely used in electric vehicles and energy storage system as a solid electrolyte in the future.”

The study was financially supported by the Dual Use Technology Program of the Institute of Civil Military Technology Cooperation that received financial resources from the Ministry of Trade, Industry and Energy (Minister Sung, Yun-mo) and the Defense Acquisition Program Administration (Minister Wang, Jung-Hong).

The study was also funded by the Institutional Research Program of the Korea Institute of Science and Technology and the Technology Development Program to Solve Climate Changes of the National Research Foundation supported by the Ministry of Science and ICT (Minister Choi, Ki-young).

The study results have been published online in the Nano Letters, a leading international journal in the fields of nanoscience and nanotechnology.