Nov 30 2017

For more than 400 years, humanity has been pointing telescopes skyward, peering into the depths of space to ask fundamental questions about the nature of the universe.

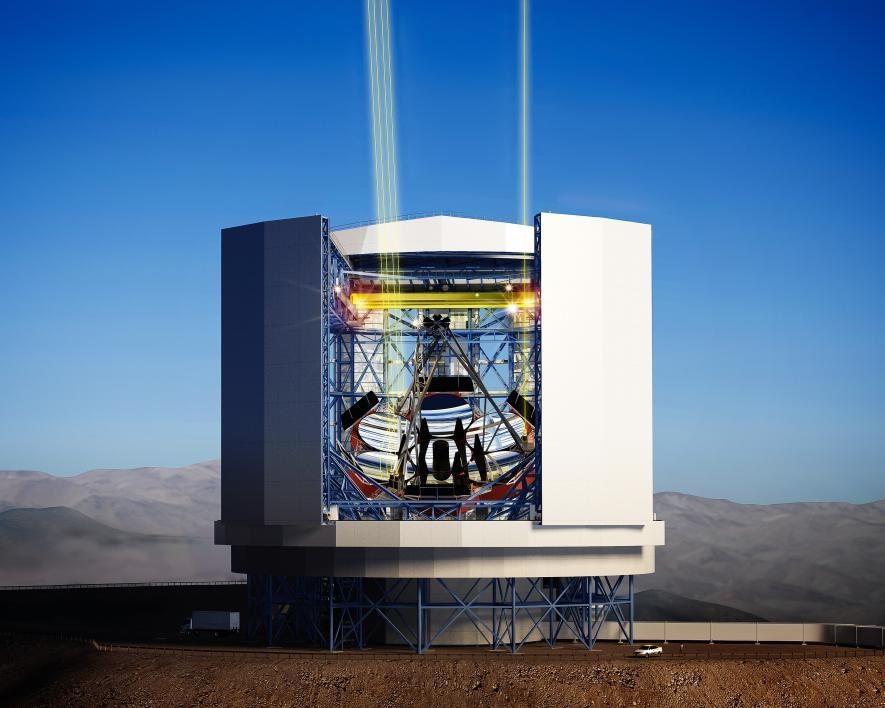

A rendering of the side view of the Giant Magellan Telescope. (Credit: Mason Media Inc./GMTO Corp.)

A rendering of the side view of the Giant Magellan Telescope. (Credit: Mason Media Inc./GMTO Corp.)

Even today, many of those essential questions remained unanswered. Arizona State University has joined an ambitious project that seeks to solve some of the biggest mysteries.

The Giant Magellan Telescope Organization (GMTO) is an international consortium of universities and institutions dedicated to building the largest, most advanced optical telescope to date. The Giant Magellan Telescope (GMT) will give us a closer look at the first stars and galaxies to ever exist. It will also help us understand planets outside of our own solar system — including ones that could support life.

RELATED: Q&A: What can we learn from the world’s largest telescope?

“Really big, exciting scientific advances are created by new instrumentation. To be serious about studying space, other planets, more distant parts of our galaxy and our universe, then we need to join in these partnerships,” said Lindy Elkins-Tanton, director of ASU’s School of Earth and Space Exploration (SESE). “So I’m excited that we’ve taken this leap institutionally to join the great partnership of what’s going to be a beautiful and transformational instrument.”

Destined for Las Campanas Observatory in Chile, the GMT is slated to be the first completed telescope to qualify as an “extremely large telescope” — defined as an optical telescope whose mirrors measure between 20 to 40 meters across. Upon planned completion in 2026, the GMT will boast an optical surface of 24.5 meters in diameter, which is a little longer than a bowling lane.

Earlier this month, the telescope’s fifth of its seven mirrors was cast from borosilicate glass melted in a 2,100-degree rotating oven at the Richard F. Caris Mirror Lab. This gives the mirrors a parabolic shape as they cool over a three-month period, which saves time on polishing.

The GMT’s mirrors will be arranged like lotus flower petals. Six circular off-axis mirrors, each weighing 17 tons — as much as two large elephants — will surround a central, on-axis mirror. Each mirror will be coated in a layer of aluminum just a few atoms thick to create the all-important reflective surface.