A recent research paper published in the journal Nature Communications discussed the fabrication of large-area single-crystal two-dimensional (2D) gold flakes with thickness on a nanometer scale using a chemical etching method. The gold flakes’ unique properties allow the realization of plasmonic nanostructures with nanoscale optical confinement and can have potential applications in nanophotonics.

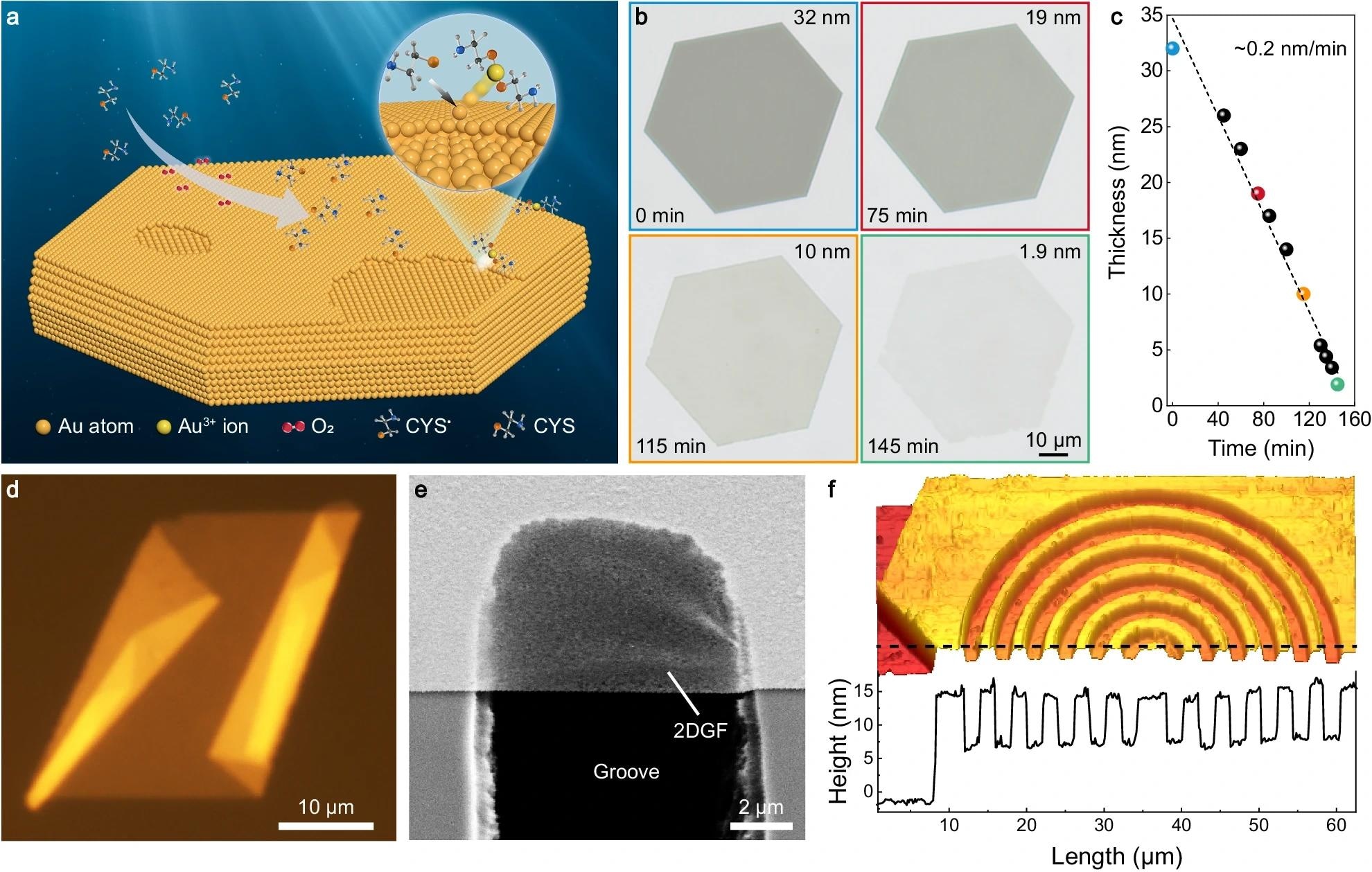

A Schematic illustration of the atomic-level precision etching approach for fabricating 2DGFs. The light blue arrow shows the reaction of cysteamines with oxygen molecules to form cysteamine radicals (CYS cysteamine, CYS• cysteamine radical). Inset, enlarged view of the etching of gold atoms with cysteamine radicals to form a soluble gold-thiolate complex. b Optical transmission micrographs of a gold flake taken at various etching times. c Measured thickness of the gold flake as a function of the etching time. The dashed line is a linear fit to the measured data points. d Optical reflection micrographs of a 2DGF folded on itself. e Scanning electron microscopy image of a 3.8-nm-thick 2DGF suspended across a groove. f Atomic force microscopy (AFM) image of a gold flake locally etched to implement a concentric ring pattern. A line scan along the indicated dashed line is also shown. Image Credit: https://www.nature.com/articles/s41467-024-47133-7

A Schematic illustration of the atomic-level precision etching approach for fabricating 2DGFs. The light blue arrow shows the reaction of cysteamines with oxygen molecules to form cysteamine radicals (CYS cysteamine, CYS• cysteamine radical). Inset, enlarged view of the etching of gold atoms with cysteamine radicals to form a soluble gold-thiolate complex. b Optical transmission micrographs of a gold flake taken at various etching times. c Measured thickness of the gold flake as a function of the etching time. The dashed line is a linear fit to the measured data points. d Optical reflection micrographs of a 2DGF folded on itself. e Scanning electron microscopy image of a 3.8-nm-thick 2DGF suspended across a groove. f Atomic force microscopy (AFM) image of a gold flake locally etched to implement a concentric ring pattern. A line scan along the indicated dashed line is also shown. Image Credit: https://www.nature.com/articles/s41467-024-47133-7

2D Single Crystal Metals for Nanophotonics

2D metals, especially 2D gold, are now extensively used in nanophotonic research due to their benefits, such as quantum effects in electric and optical properties, optical transparency, and good chemical stability, all of which help enhance the light-matter interaction at the nanoscale.

In the past, different wet chemical methods were employed to prepare 2D ultrathin gold flakes of a single nanometer thickness. However, this was tough to achieve because of limitations caused by proportional increases in thickness and size over time. Furthermore, wet chemical methods faced difficulty controlling the thickness of 2D gold precisely, even though optimizing optical and electrical properties is crucial for various applications.

Many studies have achieved ultrathin 2D gold films on dielectric substrates via organosilane monolayers, seeding, or adhesive layers like metals. However, the performance of these films was affected by electron scattering losses brought on by their granular polycrystalline structure. Additionally, the films are harder to separate from substrates due to seeding layers or adhesion, limiting their ability to integrate with other devices.

Preparation of 2D Gold Flakes

In the present study, 2D gold flakes were lifted from the substrate and deposited onto required structures using a polydimethylsiloxane (PDMS)-assisted transfer printing method. The water vapor was evaporated to form micrometer-scale droplets, carefully transferred, and aligned to the desired structure or surface at room temperature.-

Prepared gold flakes were patterned utilizing electron beam lithography (EBL) with a resist mask. Atomic-level precision etching (ALPE) follows the process of etching the exposed area and is controlled by exposing it to an electron beam, etching using an aqueous solution of cysteamine, and spin coating a resist on the surface. Subsequently, transmission electron microscopy (TEM) and atomic force microscopy (AFM) were used to analyze the crystalline structure and surface morphology of the as-prepared gold flakes. The electric properties were evaluated using a four-probe method based on a Hall-Bar structure.

Results and Observations

The AFM images obtained from different locations of the 2D gold flakes show the uniform atomic monolayer-by-monolayer etching process, which helps maintain the initial quality of the flakes and produces large-area 2D gold flakes with uniform thickness. The TEM images of the 2D gold flakes show a thickness of 3.7 nm. In contrast, the crossectional TEM images depict 10 atomic planes of gold, which stabilize the flakes for six months under ambient conditions.

This study used a precise method to prepare single-crystal 2D gold flakes called ALPE to overcome the lateral size-thickness relationship in wet chemical etching. ALPE helps fabricate large-area 2D gold flakes with very low thickness (1 nm). The significant improvement of the optical properties of these gold flakes due to quantum effects can be attributed to the drastic reduction in thickness while maintaining a smooth and single structure. The 2D gold flakes prepared by the authors possess crystalline quality and excellent continuity, which makes them promising candidates for transparent and flexible electrodes in optoelectronic devices.

Notably, the etching happens at the edges of the gold flakes, without any difference in the size and shape of the etched flakes, which is a central criterion for preparing gold flakes with large areas. The estimated etching rate was ~0.2 nm/minute, mainly depending on the cysteamine concentration.

The evaluation of electric properties confirmed the structural quality of the flakes. As the thickness reduces from 9 to 1.4 nm, sheet resistance will increase from 9 to 530 Ω/square. Hence, a noteworthy decrease in sheet resistance of 2D gold flakes can be attributed to the lower electron scattering losses. ALPE can also be utilized in localized areas to prepare micro/nanostructures. This approach is also useful in preparing other metal flakes, such as copper, silver, and others.

Conclusions

To summarize, this research successfully demonstrated the production of 2D single-crystal gold flakes with a minimal thickness of 1 nm and lateral dimensions extending over hundreds of micrometers through the application of the ALPE technique. The etching conditions can also be further optimized to reduce the thickness of the 2D gold flakes. The research outcomes underscore the superior quality of the gold flakes and their adaptability for uses in nanopatterning and transfer printing, facilitating the creation of photonic devices and structures at the nanoscale with minimized loss.

Additionally, the remarkable properties of 2D gold flakes, such as their exceptional plasmonic response, enhanced optical nonlinearity due to quantum confinement, high transparency, and ease of transfer, make them valuable resources across a wide range of research fields, including physics, chemistry, electronics, and mechanics.

Article Revisions

- Apr 8 2024 - Added in Alternative text as well as thumbnail image text.